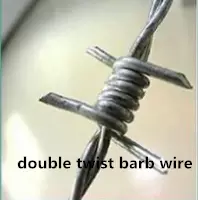

Keywords: Barbed Wire, Razor Barbed Wire, Wire Fencing, Wire Mesh & Netting

The barbed wire is an isolation protective net made by winding the barbed iron wire on the main wire (strand wire) through a barbed wire machine, and through various weaving processes.

Raw material: high-quality low-carbon steel wire. Surface treatment process: electro-galvanizing, hot-dip galvanizing, plastic coating, plastic spraying. There are blue, green, yellow and other colors. Uses: Used for isolation and protection of grassland boundaries, railways, highways, etc.

![]()

Positive twisting method: It is to twist two iron wires or multiple iron wires into a double-stranded iron wire rope and then wind the barbed wire around the double-stranded iron wire .

Reverse twisting method: Firstly, the barbed wire is wound on the main wire (that is, a single iron wire) and then an iron wire is twisted and braided to form a double-strand barbed wire.

Positive and negative twisting method: It is twisting in the opposite direction from the direction where the barbed wire is wound around the main iron wire. It is not twisted in one direction.